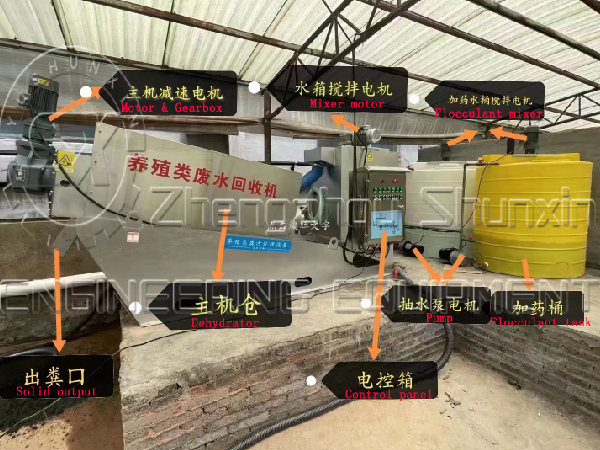

The Multi-plate Screw Press Dewatering Machine is an advanced sludge dewatering equipment designed to treat various types of sludge from municipal and industrial wastewater treatment plants. It combines the functions of concentration and dewatering, offering a compact, efficient, and energy-saving solution for reducing sludge volume and moisture content.

Working Principle

The Multi-plate Screw Press Dewatering Machine operates on the principle of slow-speed screw extrusion and multi-disc filtration. Here’s how it works:

1.Sludge Feeding: The sludge is pumped into the flocculation tank where it is mixed with polymer flocculants to form larger flocs.

2.Gravity Thickening: The flocculated sludge enters the dewatering drum, where the free water is filtered out through gaps between the fixed and moving discs by gravity.

3.Screw Extrusion: A screw shaft rotates at low speed, gradually conveying the thickened sludge toward the discharge end. During this process, the gaps between the discs become narrower, applying increasing pressure and squeezing out more water.

4.Sludge Cake Discharge: The dewatered sludge, now in a cake form, is discharged at the end of the screw press, while the filtrate is collected and sent for further treatment or recycling.

Advantages

1.Continuous and Automatic Operation: Fully automatic control reduces the need for manual intervention.

2. Energy Efficient: Low-speed operation consumes less power compared to traditional centrifuges.

3. Low Water and Chemical Consumption: Requires minimal rinsing water and flocculants.

4. Compact Design: Small footprint, easy installation, and low noise.

5. Anti-clogging Structure: The self-cleaning function of moving and fixed rings prevents clogging, allowing continuous operation.

6. Corrosion Resistance: Made from stainless steel or other corrosion-resistant materials for long service life.

7. Simple Maintenance: Fewer moving parts lead to lower maintenance requirements and costs.

8. Environmentally Friendly: Reduces sludge volume, lowering disposal costs and environmental impact.

Working Video